PFPE Heat Transfer Fluids

we take pride in being trusted distributors and suppliers of specialty chemical products

Description

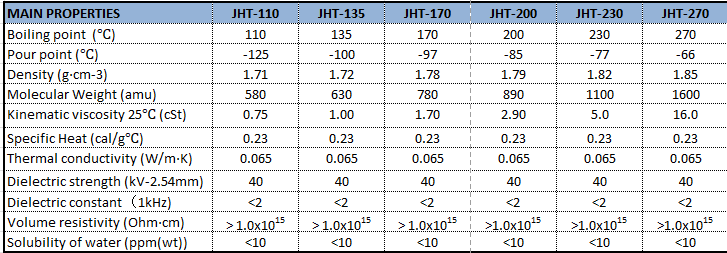

Technical Properties

Ideal for heat transfer applications with a wide liquid range (-50°C to 270°C), non-conductive properties, and chemical stability.

Features and Benefits

- High thermal stability

- Good Heat conversion capability

- Broad range of operating temperatures

- No flash, fire or auto-ignition points

- Bromine Free

- No toxicity

- None Ozone Depletion Potential (ODP)

- High ESCR (Stress Crack Resist.)

- Low Moisture Absorption

- Good dielectric properties

- Chemically inert

- Compatible with metals, plastics and elastomers

- No risk of explosion

- Low Volatility

- High Purity

- Non-Flammable

- UV & Radiation (Gamma) Resistant

- No corrosiveness or reactivity to contact materials

Main Applications

- Component Immersion

- Package leakage testing fluids in Semiconductor

- Wafer Etching

- Ion Implantation

- Vapor welding fluids in Semiconductor

- PFPE Chemical additives

- Data center coolant

- Replacement of other fluorinated fluids

- Recirculating chillers

- Radar Equipment

- Transformers

- UF6 Production

- Nuclear, Military and aerospace

- Cooling Towers

- Cooling Towers

- Freeze Dryers

Our HT fluids offer a seamless transition from industry-leading brands, providing direct replacements for:

3M Products

- Novec Engineered Fluids

- Fluorinert Electronic Liquids

Syensqo / Solvay Products:

- Galden range of fluids

Key Advantages

- Direct Compatibility: Our HT fluids are fully miscible with existing PFPE and PFA products.

- No Wastage: There's no need to flush or remove your current fluids, eliminating costly downtime and product loss.

- Seamless Integration: Our products maintain the high performance you expect, ensuring continuity in your operations.

Technical Specifications

- Wide Temperature Range: Stable in thermal conditions above 300°C, with continuous use temperature up to 290°C in the presence of oxygen.

- Excellent Chemical Stability: Resistant to aggressive acids and bases, ensuring long-term performance

- Superior Dielectric Properties: High electrical resistivity, making them ideal for semiconductor manufacturing tools

- Low Surface Tension: Capable of wetting almost all conventional sealing and gasket materials

Material Compatibility

Our HT fluids are compatible with a wide range of materials, including:

- Metals: AISI 316, Copper, Brass, Iron, Nickel, Aluminum

- Plastics: PE low density, Polypropylene, Polycarbonate, ABS copolymer, PET, PMMA

- Elastomers: Butyl rubber, NBR, EPDM, Natural rubber, Silicone rubber, PTFE

- Safety and Environmental Considerations

- Non-hazardous: No flash point, explosion hazard, or toxicity

- Environmentally friendly: Long shelf life and thermal stability reduce waste and environmental impact

By choosing our HT fluids, you ensure a smooth transition without compromising on performance or safety. Contact us today to learn how our products can seamlessly integrate into your existing systems and processes.

Need more help?

Don’t hesitate to contact us for more information about company or service

+44(0)7785 738102

sales@chemtitan.com